Lean Agile Techniques to Streamline Processes and Save Resources

Lean thinking and agile practices, often referred to as agil lean, have transformed how organizations streamline processes and save resources. By focusing on reducing waste and increasing efficiency, these methodologies help you deliver value faster. The lean-agile methodology emphasizes adaptability and collaboration, ensuring workflows align with customer needs. For example, prioritizing customer value prevents unused features, while iterative development reduces rework. Lean project management fosters continuous improvement, enabling teams to optimize workflows. In supply chains, both lean and agile approaches enhance responsiveness by minimizing excess inventory. These strategies not only improve outcomes but also create a culture of efficiency and accountability.

Key Takeaways

Lean thinking cuts waste and boosts efficiency. It helps teams work faster.

Agile methods focus on teamwork and flexibility. Teams can adapt to changes quickly.

Using both Lean and Agile creates balance. It improves work and makes customers happy.

Regular reviews and feedback help teams learn. They can fix problems and work better.

Tools like Kanban boards and feature flags help teams stay organized. They make tasks easier and improve product quality.

Understanding Lean and Agile

What is Lean?

Principles of reducing waste and maximizing efficiency.

Lean focuses on eliminating waste to improve efficiency and streamline processes. Waste can take many forms, such as overproduction, unnecessary steps, or waiting times. By identifying and removing these inefficiencies, you can create workflows that maximize productivity. Lean thinking encourages you to focus on what adds value to the customer while cutting out anything that doesn’t. For example, Toyota revolutionized manufacturing by implementing Lean principles, reducing waste, and enhancing operational efficiency.

Delivering customer value through optimized workflows.

Lean emphasizes delivering value to customers by optimizing workflows. This involves analyzing each step in a process to ensure it contributes to the final product or service. In healthcare, organizations like Brigham and Women’s Hospital have used Lean methodologies to improve patient outcomes by streamlining operations. By focusing on customer needs, Lean helps you align your processes with what matters most.

What is Agile?

Core principles of adaptability and iterative development.

Agile prioritizes adaptability and iterative development to respond quickly to changing requirements. Instead of delivering a complete product at once, Agile encourages you to work in smaller increments, known as sprints. This approach allows you to gather feedback early and make adjustments as needed. Agile supply chains, for instance, use this flexibility to adapt to market demands and ensure timely delivery.

Collaboration and transparency in Agile practices.

Agile fosters collaboration and transparency by encouraging open communication among team members and stakeholders. Regular meetings, such as daily stand-ups, keep everyone aligned and informed. This culture of openness ensures that teams can quickly address challenges and stay focused on delivering value. ING, a financial institution, became Germany’s first agile bank by adopting these principles, improving both efficiency and customer satisfaction.

How Lean and Agile Work Together

Combining Lean's efficiency with Agile's flexibility.

Lean and Agile complement each other by combining Lean’s focus on efficiency with Agile’s adaptability. While Lean reduces waste and optimizes workflows, Agile ensures you can respond to changes effectively. Together, they create a balanced approach that enhances productivity and customer satisfaction. For example, Lean project management can integrate Agile’s iterative cycles to deliver results faster.

Shared focus on reducing waste and increasing efficiency.

Both Lean and Agile share a commitment to reducing waste and improving efficiency. Lean eliminates unnecessary steps, while Agile minimizes delays by breaking work into manageable tasks. However, combining these methodologies can present challenges. Cultural resistance or conflicting priorities may arise, but maintaining a focus on customer value can help you align these approaches successfully.

Reducing Waste in Processes

Types of Waste in Lean

Overproduction, waiting, and other inefficiencies.

Lean thinking identifies eight common types of waste that hinder efficiency. These include overproduction, waiting, defects, and unnecessary motion. Overproduction occurs when you create more than what is needed, leading to excess inventory. Waiting happens when delays disrupt workflows, such as idle time between tasks. Defects require rework, which wastes time and resources. Unnecessary motion, like excessive movement of materials or people, also reduces productivity.

Type of Waste | Description |

|---|---|

Defects | Errors that require correction. |

Overproduction | Producing more than is needed. |

Waiting | Idle time when work is delayed. |

Non-utilized talent | Underutilization of skills and abilities of employees. |

Transportation | Unnecessary movement of products or materials. |

Inventory | Excess products and materials not being processed. |

Motion | Unnecessary movements by people. |

Extra processing | More work or higher quality than is required. |

By addressing these inefficiencies, you can reduce waste and improve overall productivity.

Examples of waste in project management and software development.

In project management, overproduction might involve creating reports no one uses. Waiting could stem from delayed approvals. In software development, defects like bugs require additional testing and fixes. Excessive documentation can also slow progress. Lean project management helps you identify and eliminate these inefficiencies, ensuring resources are used effectively.

Waste in Agile Workflows

Inefficient communication and misaligned goals.

Agile workflows often face challenges like poor communication and unclear objectives. Misaligned goals can lead to wasted effort on tasks that do not deliver value. For example, teams may work on features that do not align with customer needs. To address this, you should foster collaboration and ensure all team members understand the project’s priorities.

Excessive documentation and lack of prioritization.

Excessive documentation can slow down agile processes. Instead of focusing on delivering value, teams may spend too much time on unnecessary paperwork. A lack of prioritization can also lead to wasted effort on low-value tasks. By adopting lean thinking, you can streamline workflows and focus on what truly matters.

Benefits of Waste Reduction

Improved team morale and resource allocation.

Reducing waste boosts team morale by creating a more efficient and rewarding work environment. When you eliminate unnecessary tasks, team members can focus on meaningful work. This improves job satisfaction and productivity. Better resource allocation ensures that time, money, and talent are used effectively.

Enhanced outcomes through streamlined processes.

Waste elimination leads to streamlined processes, which enhance outcomes. By focusing on high-value tasks, you can deliver better results faster. Lean and agile practices, such as just-in-time delivery, help you achieve this by aligning workflows with customer needs. This approach not only saves resources but also improves efficiency.

Lean-Agile Techniques for Increasing Efficiency

Prioritizing Customer Value

Focusing on high-value tasks and customer feedback.

Prioritizing customer value lies at the heart of the lean-agile methodology. You can achieve this by focusing on tasks that deliver the most value to your customers. Listening to feedback ensures your efforts align with their needs. For example:

In software development, companies like Spotify use cross-functional teams to adapt quickly to user feedback.

In manufacturing, Toyota applies lean principles to reduce waste and maximize value.

In healthcare, Brigham and Women’s Hospital enhances patient care by redesigning processes based on collaboration and feedback.

In finance, ING validates innovations with customers to allocate resources effectively.

By adopting these practices, you can maximize value and improve efficiency across industries.

Continuous Improvement

Retrospectives and feedback loops for learning.

Continuous improvement is essential for streamlining processes and increasing efficiency. Retrospectives allow your team to reflect on completed work and identify areas for improvement. Feedback loops provide opportunities to learn and adapt. Successful examples include:

Toyota’s just-in-time production system fosters a culture of continuous improvement by empowering employees.

Microsoft uses DevOps practices and CI/CD pipelines to enhance software delivery and incorporate regular feedback.

ING implements Agile practices and the Scaled Agile Framework (SAFe) to focus on customer-centric product delivery.

GE Aviation integrates Lean Six Sigma principles to optimize processes and encourage employee-driven improvements.

These initiatives demonstrate how continuous improvement can reduce waste and enhance operational efficiency.

Team Collaboration and Transparency

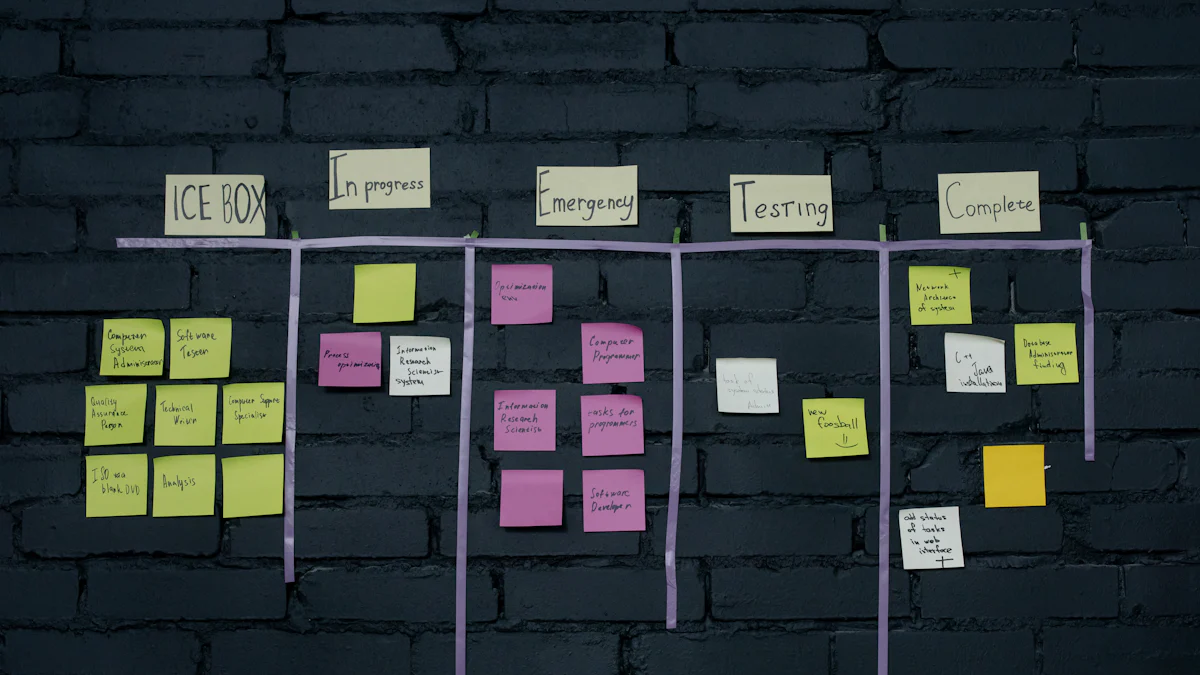

Cross-functional teams and visual tools like Kanban boards.

Collaboration and transparency are vital for flexibility and responsiveness. Cross-functional teams bring diverse skills together, enabling you to tackle challenges effectively. Tools like Kanban boards improve visibility and streamline workflows. They allow your team to:

View task statuses on a centralized platform, enhancing transparency.

Track dependencies and collaborate on tasks, ensuring smooth handovers.

Use swimlanes to categorize tasks by department or project phase, promoting clarity on roles.

Leverage online Kanban boards with features like global search and task dependencies for better coordination.

These practices help you optimize processes, reduce waste, and achieve enhanced efficiency.

Iterative Development

Delivering value faster with sprints and small batches.

Iterative development allows you to deliver value quickly by breaking work into smaller, manageable parts. This approach focuses on creating and testing small batches of a product during short cycles, often called sprints. By doing so, you can identify and resolve issues early, improving the overall quality of your product.

This method also enhances flexibility and responsiveness. You can adjust your work based on user feedback after each iteration. For example, agile teams often use iterative development to align their efforts with customer needs. Regular feedback ensures that the final product meets expectations.

Iterative development also improves collaboration. Team members work closely throughout the process, fostering better communication and teamwork. Additionally, this approach supports better risk management. Evaluating risks after each sprint helps you create strategies to avoid delays. By focusing on small, incremental improvements, you can achieve continuous improvement and maximize value for your customers.

Key benefits of iterative development include:

Flexibility to adapt based on feedback.

Better risk management with regular evaluations.

Frequent feedback from users and stakeholders.

Enhanced collaboration among team members.

Feature Flag Technology

Controlled feature releases to reduce risk.

Feature flag technology allows you to release new features in a controlled manner. Instead of launching a feature to all users at once, you can enable it for a small group. This incremental rollout minimizes risks associated with live updates. For instance, ZeroFlucs used feature flags to optimize its infrastructure, reducing costs by 60% while maintaining a consistent customer experience.

This approach also supports lean project management by aligning with just-in-time production principles. You can test features in real-world conditions without disrupting operations. This ensures operational efficiency and reduces waste caused by rework or downtime.

Faster feedback cycles and experimentation.

Feature flags enable faster feedback cycles. You can gather insights from users quickly, allowing you to refine features based on real-world data. This accelerates customer-centric product delivery and helps you focus on maximizing value. Experimentation becomes easier as you can test multiple variations of a feature simultaneously.

By integrating feature flag technology into your workflows, you can enhance efficiency, reduce waste, and improve flexibility. This tool empowers you to deliver high-quality products while maintaining a focus on customer value.

Tools and Frameworks for Lean-Agile Practices

Kanban Boards

Visualizing workflows and managing work-in-progress.

Kanban boards help you visualize workflows and manage tasks effectively. They provide a clear representation of your team’s progress, making it easier to identify bottlenecks. By limiting work-in-progress (WIP), Kanban boards encourage focus and reduce multitasking. This approach ensures smoother workflows and faster task completion.

Using Kanban boards also enhances collaboration. A centralized platform allows your team to track tasks transparently, promoting accountability. Regular reviews of the board help you identify inefficiencies and implement changes for continuous improvement. For example, you can use swimlanes to categorize tasks by priority or department, ensuring clarity and better workload management.

Key benefits of Kanban boards include:

Faster task completion through a pull system.

Enhanced team collaboration and transparency.

Reduced bottlenecks and optimized workload management.

The PDCA Cycle

Structured continuous improvement in operations.

The PDCA (Plan-Do-Check-Act) cycle provides a structured approach to improving processes. It helps you identify problems, test solutions on a small scale, and implement successful strategies across your organization. This method fosters a culture of continuous improvement by encouraging regular evaluations and adjustments.

For example, you can use the PDCA cycle to streamline a production process. Start by planning changes based on identified issues. Implement these changes on a small scale during the "Do" phase. Evaluate the results in the "Check" phase to determine their effectiveness. Finally, apply successful strategies organization-wide in the "Act" phase. This systematic approach ensures sustainable improvements over time.

Scrum Framework

Organizing work into sprints for iterative progress.

The Scrum framework helps you organize work into short cycles called sprints. Each sprint focuses on delivering a specific set of tasks, allowing you to make progress incrementally. This iterative approach ensures flexibility and enables you to adapt to changing requirements.

Scrum emphasizes collaboration through regular meetings like daily stand-ups and sprint reviews. These meetings keep your team aligned and focused on shared goals. By breaking work into smaller, manageable parts, Scrum reduces complexity and enhances productivity.

Several frameworks build on Scrum principles to scale agile practices for larger teams. For instance:

SAFe integrates lean and agile methodologies to coordinate multiple teams.

LeSS applies Scrum at scale, emphasizing cross-team collaboration.

Scrum@Scale aligns growing organizations with common goals through coordinated efforts.

These frameworks help you implement agile practices effectively, ensuring better outcomes and streamlined workflows.

Feature Flag Platforms

Tools like LaunchDarkly for managing feature toggles

Feature flag platforms, such as LaunchDarkly, empower you to manage feature toggles effectively. These tools allow you to control which features are visible to users without deploying new code. By using feature flags, you can test new functionality in real-world conditions while minimizing risks. This approach aligns with Lean-Agile principles by promoting flexibility, reducing waste, and enabling faster feedback cycles.

Feature flags enhance your ability to iterate and experiment. They let you test robust functionality, not just cosmetic changes. For example, you can release a feature to a small group of users, gather feedback, and refine it before a full rollout. If the feature causes issues, you can disable it instantly without disrupting the entire system. This capability helps you mitigate risks and maintain operational stability.

Feature flag platforms also foster collaboration across teams. Marketing, design, and engineering can work together more effectively by using real market feedback. For instance:

Marketing teams can test promotional features with specific user segments.

Designers can validate user interface changes in production environments.

Engineers can focus on delivering high-quality functionality without worrying about immediate deployment.

These tools benefit various roles within your organization:

QA teams can test functionality directly in production and validate changes.

Sales and customer support teams can manage entitlements for specific users.

Product managers can control beta program access and align feature releases with business goals.

Platforms like LaunchDarkly streamline these processes, enabling you to deliver value faster. By integrating feature flags into your workflows, you can experiment confidently, adapt quickly, and ensure your efforts align with customer needs. This approach not only saves resources but also enhances your team’s ability to innovate and respond to change.

Real-World Applications of Lean-Agile

Project Management

Streamlining workflows and improving team alignment.

Lean-agile practices transform project management by streamlining workflows and fostering team alignment. You can use tools like Kanban boards to visualize tasks and identify bottlenecks. This approach ensures that everyone understands their responsibilities and focuses on high-priority tasks. Regular stand-ups and retrospectives encourage open communication, helping your team address challenges quickly.

For example, ING adopted agile principles to improve collaboration and deliver projects faster. By breaking work into smaller increments, you can adapt to changes and maintain alignment with project goals. This method not only enhances productivity but also boosts team morale by creating a transparent and efficient work environment.

Supply Chain Management

Reducing waste and enhancing responsiveness.

Lean supply chain and agile supply chain strategies help you reduce waste and improve responsiveness. By eliminating overproduction, you can allocate resources more effectively. Frequent feedback loops minimize waiting times, while just-in-time delivery prevents excess inventory.

Small batches prioritize essential tasks, reducing overprocessing.

Co-located teams and digital tools streamline communication, cutting unnecessary transport.

Continuous testing and early issue detection prevent defects, ensuring quality.

For instance, Toyota’s lean supply chain principles focus on just-in-time delivery and efficient workflows. These practices allow you to respond quickly to market demands while minimizing waste. By adopting these strategies, you can enhance operational efficiency and meet customer needs more effectively.

Software Development

Accelerating delivery with iterative development and feature flags.

Lean-agile techniques accelerate software development by focusing on iterative progress and continuous improvement. You can use value stream mapping to identify inefficiencies and eliminate non-value-adding activities. Test-driven development and continuous integration improve software quality, while Kanban boards help you track progress and resolve bottlenecks.

Spotify uses the "Spotify Model" to scale agile practices, enabling rapid feature delivery.

Intel applies SAFe to enhance collaboration and reduce time-to-market.

The U.S. Department of Defense leverages lean-agile methods to streamline procurement processes.

Feature flags further enhance responsiveness by allowing controlled feature releases. You can test new functionality with a small user group, gather feedback, and refine the product before a full rollout. This approach reduces risks and ensures that your software aligns with customer expectations.

The lean-agile methodology offers proven strategies for streamlining processes and saving resources. By focusing on customer value, you can ensure that your efforts align with real needs. Continuous improvement, supported by tools like Kanban boards and the PDCA cycle, helps you refine workflows and eliminate waste. Lean project management fosters collaboration and adaptability, enabling you to respond quickly to changes. Across industries like manufacturing, healthcare, and finance, the lean-agile methodology has delivered higher productivity and better outcomes. Adopting these practices empowers you to create efficient, adaptable workflows that drive success.

FAQ

What is the main difference between Lean and Agile?

Lean focuses on reducing waste and maximizing efficiency in workflows. Agile emphasizes adaptability and iterative development to respond to changes quickly. While both aim to improve processes, lean prioritizes efficiency, and agile focuses on flexibility.

How can Lean-Agile practices benefit small teams?

Lean-agile practices help small teams by streamlining workflows and improving collaboration. Tools like Kanban boards and iterative development allow teams to focus on high-value tasks, reduce waste, and adapt to changes effectively.

What industries can apply Lean-Agile techniques?

Lean-agile techniques work across industries like manufacturing, healthcare, software development, and supply chain management. These methods improve efficiency, reduce waste, and enhance responsiveness, making them versatile for various sectors.

How do Kanban boards support Lean-Agile practices?

Kanban boards visualize workflows, helping you track tasks and identify bottlenecks. They promote transparency and collaboration, ensuring your team focuses on high-priority tasks. This aligns with lean-agile principles of efficiency and adaptability.

Can Lean-Agile techniques work for remote teams?

Yes, lean-agile techniques suit remote teams. Digital tools like online Kanban boards and virtual stand-ups enable collaboration and transparency. These practices ensure alignment and efficiency, even in distributed work environments.

See Also

AWS Feature Toggles: Enhancing Your Development Process

Simplifying Feature Management in .NET Core for Developers

Selecting the Top Enterprise Feature Flag Tools for 2025