Mastering Lean Product Development for Agile Teams in 2025

Lean product development software has become essential for agile teams striving to stay competitive in 2025. By focusing on eliminating waste and improving efficiency, lean practices help you deliver faster, reduce costs, and enhance customer satisfaction. Metrics play a key role in tracking progress, ensuring your team continuously improves the product lifecycle.

Adopting lean empowers teams to optimize workflows and foster a culture of learning. It reduces speed to market while maintaining quality, enabling you to create better products. Tools like feature flags make this process even more effective. They allow you to release features incrementally, gather real-time feedback, and refine your product based on user insights. This approach aligns perfectly with lean principles, ensuring continuous learning and improvement.

Key Takeaways

Lean product development means giving customers value and reducing waste. It helps teams make good products quickly.

Knowing what customers need is very important. Do market research to learn what users want and adjust your product to fit.

Try tools like feature flags to release features step by step. This helps get feedback fast and lowers risks while building.

Always look for ways to improve by checking your work often. Small fixes can make big differences over time.

Work together with all team members. Talking openly and having shared goals makes work faster and products better.

Understanding Lean Product Development

What is Lean Product Development?

Lean product development focuses on creating value for your customers while minimizing waste throughout the product development process. This approach originated at Toyota in the mid-20th century, evolving from the Toyota Production System. Toyota applied principles like just-in-time production and waste reduction to product design, which led to the development of lean methodologies. Unlike traditional methods, lean emphasizes flexibility, speed, and efficiency. It prioritizes customer needs and ensures that every step in the process adds value.

Key differences between lean and traditional product development include:

Lean emphasizes reducing waste and creating value based on customer needs.

Lean uses resources efficiently, while traditional methods often follow rigid structures.

Lean aims for speed and flexibility, contrasting with the slower pace of traditional approaches.

By adopting lean, you can streamline your product development process and deliver better results faster.

Core Principles of Lean Product Development

Maximizing Customer Value

Lean product development revolves around a customer-centric approach. You focus on understanding customer needs and delivering features that provide the most value. This principle ensures that your efforts align with what matters most to your users, improving customer satisfaction and loyalty.

Identify and Eliminate Waste

Waste in the product development process includes anything that doesn’t add value to the customer. Lean encourages you to identify and eliminate waste, such as unnecessary steps, delays, or overproduction. By doing so, you can improve efficiency and reduce costs.

Continuous Improvement

Lean transformation thrives on continuous improvement. This principle encourages you to refine both the product and the process. Iterative cycles and feedback loops help you learn quickly and make adjustments that enhance quality and performance.

How Lean Product Development Aligns with Agile Methodologies

Lean and agile share a common goal: delivering customer value efficiently. Both approaches embrace change and use iterative cycles to refine products. Lean’s focus on eliminating waste complements agile’s emphasis on collaboration and adaptability. For example, lean’s principle of “build quality in” aligns with agile practices like test-driven development. Additionally, lean’s continuous flow principles can smooth transitions between agile sprints, reducing inefficiencies and improving speed to market. Together, these methodologies create a powerful framework for delivering high-quality products.

Steps to Implement Lean Product Development

Identifying Customer Value

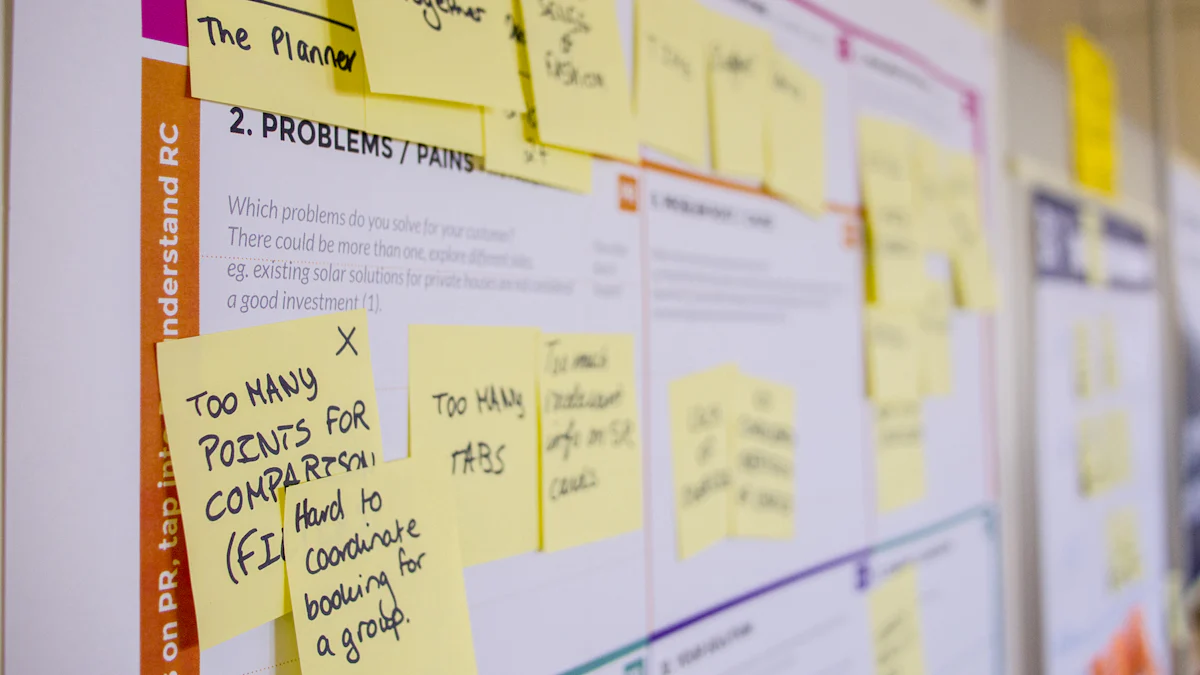

The first step in implementing lean product development is to identify value from the customer’s perspective. This ensures your efforts align with what truly matters to your users. Start by conducting thorough market research. Gather data about your industry, competitors, and target audience. Dive deeper into your audience’s psychographics to understand their motivations, values, and beliefs. Pinpoint their needs and pain points to tailor your value proposition effectively.

By focusing on customer feedback, you can refine your understanding of what users want. This approach not only helps you deliver better products but also ensures you achieve product-market fit. When you prioritize customer value, you set the foundation for a successful lean implementation.

Mapping the Value Stream

Once you identify value, the next step is to map the value stream. This process involves visualizing every step required to bring your product from concept to delivery.

Value stream mapping (VSM) is diagramming every step involved in the material and information flows needed to bring a product from order to delivery. It is a fundamental tool used in continuous improvement to identify and eliminate waste.

Value stream mapping helps you uncover inefficiencies and bottlenecks in your workflows. By analyzing these steps, you can identify areas where waste occurs and take action to improve efficiency. This tool is essential for making lean development work effectively.

Creating Flow by Eliminating Waste

Creating a smooth flow in your process is critical for lean product development. Start by identifying waste through value stream mapping. Examine each activity in your workflow to determine whether it adds value.

Find waste through value stream mapping. Identify unnecessary steps or delays in your process.

Remove or reduce the waste. Use iterative cycles and regular retrospectives to refine your workflows.

A faster flow reduces product costs and improves efficiency. Lean development focuses on enhancing the value creation stream to meet customer demands seamlessly. By eliminating waste, you ensure your process delivers maximum value while minimizing delays and inefficiencies.

A faster flow equates to a lower product cost. A lean organization realizes that the cost of a product is primarily driven by the rate of flow through the value stream.

By following these steps, you can create a streamlined process that aligns with lean principles and delivers exceptional results.

Responding to Customer Pull

Responding to customer pull is a cornerstone of lean product development. This concept ensures that your process aligns with customer demand, enabling you to deliver value efficiently. To achieve this, you must first understand what your customers truly value. Start by gathering insights through interviews, surveys, and direct observations. These methods help you identify customer needs and preferences. Tools like personas and customer journey maps can further refine your understanding of different customer segments.

Once you understand customer demand, align your workflows to meet it. Implement systems like takt time, which synchronizes production with demand, ensuring a steady flow of value. Feedback loops also play a critical role. By continuously listening to your customers, you can adapt quickly to their changing needs. This approach not only enhances the flow of your process but also reduces waste, improving the overall customer experience.

Customer pull drives faster product development by focusing your efforts on what matters most. It eliminates unnecessary steps and ensures that every action adds value. Organizations that prioritize customer pull create products that resonate with their audience, fostering loyalty and satisfaction.

Pursuing Perfection Through Continuous Improvement

Pursuing perfection is an ongoing journey in lean product development. This principle encourages you to refine both your product and process continuously. By embracing iterative cycles, you can identify areas for improvement and implement changes that enhance efficiency and quality.

Toyota exemplifies this principle through its Toyota Production System (TPS). The company focuses on waste elimination, efficiency enhancement, and delivering high-quality products. This relentless pursuit of perfection has made Toyota a global leader in lean practices.

To apply this principle, start by fostering a culture of learning within your team. Encourage regular retrospectives to evaluate what works and what doesn’t. Use data-driven insights to guide your decisions and prioritize improvements. Small, incremental changes often lead to significant results over time.

Continuous improvement ensures that your process evolves to meet customer needs effectively. It helps you stay competitive in a fast-paced market while delivering exceptional value. By striving for perfection, you can create products that exceed expectations and set new standards in your industry.

Tools and Strategies for Agile Teams

Leveraging Feature Flags for Lean Product Development

Reducing Risk with Feature Flags

Feature flags help you reduce risk by allowing you to toggle features on or off instantly. If a new feature causes issues, you can disable it without disrupting the entire system. This approach ensures stability while enabling experimentation. Teams using feature flags avoid the risks associated with large-scale deployments, making the development process safer and more efficient.

Accelerating Feedback with Controlled Releases

Feature flags enable controlled releases, allowing you to test features with a subset of users. This strategy helps you gather feedback quickly and refine your product based on real-world data. Controlled releases also let you identify potential issues early, ensuring that only polished features reach your broader audience. Faster feedback loops align with lean principles, helping you improve continuously.

Minimizing Waste by Testing Features Incrementally

Testing features incrementally prevents unnecessary investments in ideas that may not work. Feature flags let you validate concepts before committing resources to full-scale development. By focusing on what delivers value, you eliminate waste and streamline your process. This incremental approach ensures that your efforts align with customer needs and expectations.

Enabling Continuous Improvement with Real-Time Adjustments

Feature flags support continuous improvement by allowing real-time adjustments. You can refine features based on user feedback without waiting for the next release cycle. This flexibility helps you adapt quickly to changing requirements, ensuring your product evolves to meet customer demands. Continuous improvement is a cornerstone of lean product development, and feature flags make it achievable.

Benefit | Description |

|---|---|

Agility | |

Risk Reduction | They enable quick disabling of features in case of issues, minimizing disruption. |

Experimentation | Feature flags support controlled testing of new features, facilitating data-driven decisions. |

A/B Testing | Different versions of features can be tested with user groups to determine effectiveness. |

Canary Releases | New features can be gradually rolled out to a small user base to identify issues early. |

Using Kanban Boards to Visualize Work

Kanban boards provide a clear visual representation of your workflow. They help you track tasks from start to finish, ensuring transparency and accountability. By breaking down complex projects into smaller tasks, Kanban boards simplify task management and reduce cognitive load. Visual cues on the board make it easy to identify bottlenecks and prioritize work effectively. Regular reviews of the board encourage continuous improvement, helping you refine your process over time.

Benefit | Explanation |

|---|---|

Reducing Multitasking | Limiting WIP helps team members focus on completing one task at a time, reducing cognitive load. |

Transparent Workflow | Provides a clear view of who is working on what, fostering accountability among team members. |

Simplifying Task Management | Breaks down complex projects into manageable tasks, reducing cognitive load and aiding prioritization. |

Visual Cues | Helps team members quickly understand task status and identify what needs attention. |

Continuous Improvement | Encourages regular reviews of processes to identify inefficiencies and implement changes. |

Setting Work-in-Progress (WIP) Limits

Setting WIP limits ensures that your team focuses on completing tasks rather than juggling multiple responsibilities. This practice reduces multitasking and improves efficiency. To implement WIP limits effectively:

Limit multitasking to keep team members focused on their current tasks.

Map WIP limits to your team’s skills to accommodate specialists.

Maintain sufficient slack in the process to allow flexibility and responsiveness to change.

Size individual tasks consistently to prevent bottlenecks.

Map WIP limits to the team’s skills to enhance flow.

Reduce idleness by encouraging team members to assist each other.

Protect a sustainable engineering culture to maintain quality.

By setting WIP limits, you create a balanced workflow that aligns with lean principles. This approach helps you deliver value efficiently while maintaining high-quality standards.

Incorporating Iterative Feedback Loops

Incorporating iterative feedback loops into your lean product development process ensures continuous learning and improvement. This approach allows you to refine your product based on real-world insights, helping you deliver value that aligns with customer needs. By following a structured cycle, you can make informed decisions and adapt quickly to changing demands.

To implement iterative feedback loops effectively, follow these three steps:

Build: Start by shaping key assumptions about your product. Create a minimum viable product (MVP) that addresses the most critical customer needs. Release this MVP to a small group of users to test its functionality and gather initial reactions.

Measure: Establish clear metrics to evaluate your product’s performance. Collect feedback from users and compare their responses against your key performance indicators (KPIs). This step helps you identify what works and what needs improvement.

Learn: Analyze the data you’ve gathered. If the results confirm your assumptions, refine the product further. If they don’t, adjust your approach or pivot to a new direction. Repeat this cycle to ensure your product evolves in line with customer expectations.

This iterative process aligns perfectly with lean principles. It minimizes waste by focusing only on features that add value. It also accelerates learning, enabling you to make quick adjustments without overcommitting resources. By integrating feedback loops into your workflow, you create a dynamic system that prioritizes customer satisfaction and drives continuous improvement.

Tip: Use tools like feature flags to test changes incrementally and gather real-time feedback. This strategy enhances agility and reduces risk during the development process.

Overcoming Challenges in Lean Product Management

Addressing Misconceptions About Lean Practices

Misconceptions about lean product management can hinder its adoption and success. Understanding and addressing these misconceptions is crucial for your organization to fully embrace lean principles.

Lean is not limited to manufacturing. It applies to various industries, including software development and healthcare.

Lean focuses on delivering value to customers, not just cutting costs.

Lean is not a one-time project. It is a continuous journey of improvement.

Lean emphasizes quality and flow, not just speed.

Employee involvement is essential for lean success. It thrives on collaboration and team engagement.

Lean is not exclusive to large organizations. Small businesses can also benefit from its principles.

Lean fosters innovation by promoting a culture of continuous improvement.

By addressing these misconceptions, you can create a clearer understanding of lean practices within your organization. This clarity ensures that your team aligns with lean principles effectively.

Managing Resistance to Change in Teams

Resistance to change is a common challenge when implementing lean product management. To overcome this, involve your team in the change process. Their knowledge and creativity can drive innovation and improvement. Provide training and support to reduce fear of the unknown. Lead by example to demonstrate resilience and adaptability.

Clear communication is essential. Share the vision and benefits of lean practices with your team. Highlight how these changes will improve workflows and outcomes. Celebrate small wins and recognize individual efforts to build momentum. These strategies foster a positive environment and encourage your team to embrace lean principles.

Balancing Speed and Quality

Balancing speed and quality is vital in lean product management. Define and prioritize key product expectations to ensure your team delivers value efficiently. Collaborate with design teams to create Minimum Viable Products (MVPs) that meet customer needs. Secure stakeholder agreement on release plans to align goals.

Adopt iterative development and test-driven development (TDD) to maintain high standards. Use continuous integration and deployment (CI/CD) to streamline workflows. Empower your team to make decisions and trust their expertise. Incorporate customer feedback loops to refine your product continuously.

By focusing on these strategies, your organization can achieve a balance between speed and quality. This approach ensures that your lean process delivers exceptional results without compromising standards.

Ensuring Cross-Functional Collaboration

Cross-functional collaboration is essential for lean product development. It ensures that every team member contributes their expertise to create value efficiently. When teams work together effectively, they eliminate silos, improve communication, and align their efforts with customer needs.

To foster cross-functional collaboration, you need a clear strategy. Start by defining your portfolio vision and strategy. This step provides a shared understanding of goals and ensures that every team works toward the same objectives. Next, establish a portfolio governance process. This structure helps you manage decision-making and ensures accountability across teams.

Implementing a portfolio prioritization framework is another critical step. This framework allows you to focus on the most valuable tasks, ensuring that resources are used efficiently. Align your portfolio roadmap and backlog to maintain consistency between long-term goals and day-to-day activities. This alignment keeps your teams focused and prevents wasted effort.

Coordinating portfolio execution and delivery is equally important. Regular check-ins and progress updates help you track performance and address challenges quickly. Finally, monitor and improve your portfolio performance and learning. Use data to identify areas for improvement and refine your approach over time.

Collaboration thrives when you create an environment of trust and transparency. Encourage open communication and ensure that every team member understands their role in the process. By following these steps, you can build a collaborative culture that supports lean principles and drives success.

Tip: Use tools like Kanban boards and feature flags to enhance collaboration. These tools provide visibility into workflows and allow teams to adapt quickly to changes.

Trends and Innovations in Lean Product Development for 2025

The Role of AI and Automation in Lean Product Development Software

AI and automation are transforming lean product development software by streamlining workflows and reducing inefficiencies. These technologies shorten product development lifecycles and cut costs significantly. For example, AI enables faster iterations and improves design processes, helping industries like automotive and aerospace reduce time-to-market by up to 50% and costs by 30%. Pharmaceutical companies have also leveraged AI to cut drug discovery timelines by over half.

You can use AI to analyze vast amounts of data, identify patterns, and predict outcomes. This capability allows your team to make informed decisions quickly. Automation complements this by handling repetitive tasks, freeing your team to focus on high-value activities. Together, AI and automation enhance your process, enabling you to deliver better products faster while adhering to lean principles.

Enhanced Use of Feature Flags for Real-Time Adjustments

Feature flags have become indispensable for lean product development. They allow you to activate or deactivate features instantly, providing flexibility in your development process. This capability supports gradual rollouts, A/B testing, and canary releases. By releasing features to a small user group first, you can identify issues early and minimize disruption.

Feature flags also let you test different feature versions in real-time. If a feature causes problems, you can disable it without redeploying code. This approach ensures stability and supports a responsive development process. By integrating feature flags into your workflow, you can adapt quickly to customer needs and maintain a seamless user experience.

Data-Driven Decision Making in Lean Product Management

Data-driven decision-making is a cornerstone of lean product management. It reduces bias by relying on data instead of assumptions. Insights from data help you understand user behavior, preferences, and pain points. This understanding allows you to prioritize features that deliver the most value.

Using data, you can allocate resources to initiatives with the highest ROI. Data-backed decisions also foster transparency and build trust with stakeholders. By aligning your process with data insights, you can innovate effectively and create products that resonate with your audience.

The Rise of Remote-First Agile Teams and Its Impact on Lean Practices

Remote-first agile teams are transforming lean practices in 2025. The shift to remote work has redefined how teams collaborate and deliver value. You now need to rethink traditional agile ceremonies and adapt them to a distributed environment. For example, asynchronous standup updates have replaced daily in-person meetings. This change ensures that team members across different time zones stay aligned without disrupting their workflows.

Documentation has also evolved into a dynamic part of the agile process. Tools like Notion and Confluence allow teams to create living documents that adapt as projects progress. These tools ensure that everyone has access to up-to-date information, fostering transparency and reducing miscommunication.

New collaboration patterns are reshaping lean practices. Remote-first teams emphasize asynchronous communication to accommodate flexible schedules. This approach minimizes delays and keeps the process moving efficiently. Specialized roles, such as Scrum Masters and Product Owners, are becoming more critical. These roles guide teams through the lean process, ensuring that workflows remain streamlined and customer-focused.

Organizations are also reevaluating lean principles to suit remote-first environments. They are rehiring key roles to support distributed teams effectively. This shift highlights the importance of leadership in maintaining lean practices. By fostering a culture of trust and accountability, you can ensure that your team thrives in a remote-first setting.

Tip: Use tools like feature flags to enhance collaboration in remote teams. These tools allow you to test and refine features incrementally, aligning with lean principles of continuous improvement.

Remote-first agile teams demonstrate that lean practices can adapt to any environment. By embracing these changes, you can maintain efficiency and deliver exceptional value to your customers.

Adopting lean product development transforms how you deliver value. It boosts efficiency, reduces waste, and enhances product quality. By focusing on flow efficiency and smaller, frequent releases, you align closely with business outcomes. Tools like feature flags empower you to test features incrementally, reduce risks, and adapt in real time. FeatBit stands out as a reliable solution for teams starting their lean journey. Pairing lean principles with tools like Kanban boards and Kaizen meetings fosters continuous improvement. Begin implementing lean practices today to create products that truly solve customer problems effectively.

FAQ

What is the main goal of lean product development?

Lean product development aims to maximize customer value while minimizing waste. It focuses on creating efficient workflows, delivering high-quality products quickly, and continuously improving processes based on customer feedback.

How do feature flags support lean principles?

Feature flags let you release features incrementally, reducing risks and gathering real-time feedback. They help you test ideas without committing resources fully, ensuring only valuable features reach users. This aligns with lean’s focus on efficiency and continuous improvement.

Can small teams implement lean practices effectively?

Yes, small teams can adopt lean practices successfully. Start by identifying customer value, mapping workflows, and eliminating waste. Use tools like Kanban boards and feature flags to streamline processes. Lean principles work for teams of any size.

How does lean differ from traditional product development?

Lean emphasizes flexibility, speed, and customer value. Traditional methods often follow rigid structures and longer timelines. Lean focuses on eliminating waste and adapting quickly to changes, while traditional approaches prioritize detailed upfront planning.

What tools are essential for lean product development?

Key tools include feature flags, Kanban boards, and value stream mapping. Feature flags enable incremental releases and real-time adjustments. Kanban boards visualize workflows, while value stream mapping identifies inefficiencies. These tools enhance efficiency and align with lean principles.

Tip: Start with tools like FeatBit to implement feature flags and streamline your lean journey.

See Also

Understanding Feature Flags and Their Significance in 2025

The Essential Role of Feature Flags in 2025 Development

Selecting the Right Feature Flag Tools for Enterprises in 2025

Top Predictions for Collaboration Tools and Productivity in 2025